Capacitors used for power factor or harmonic filter applications have traditionally experienced some problems when transient over-voltages or over-current caused case ruptures, especially when capacitor failures involved oil leaking out. Problems such as these have caused reluctance by some engineers to specify power quality filters involving capacitors. FRAKO has innovated a number of advancements in ac power capacitor design and manufacturing techniques to resolve both of these problems.

Nearly all AC power capacitors produced today will include two forms of internal protection. They are self healing metalized polypropylene film, electrical disconnection of the capacitor in case of over-pressure.

The film self healing process typically occurs when a transient over-voltage pierces a hole through one or more layers of the metalized film. The hole can leave a conductive path between winding layers and cause a localized short circuit. The self healing process removes, by vaporization, the metallization around the hole and thus isolates the localized short.

Throughout the lifetime of a capacitor, self healing events will occur from time to time, due to transients that are typically experienced on a facility power system. With each self healing and vaporization event, the pressure inside the capacitor increases slightly.

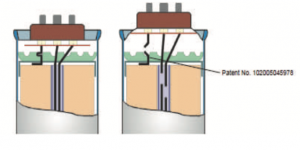

Over time, the pressure caused by self healing events builds up, and if not for an internal over-pressure disconnect device, could cause a case rupture. AC power capacitors typically have an over-pressure switch that will disconnect only two of the three phases of the capacitor, leaving power applied to one end of the third winding.

FRAKO capacitors have a patented overpressure disconnecting method that opens all three phases in the event of an overpressure condition within the capacitor. This method assures that none of the (3- phase) internal windings will have power applied after the overpressure disconnect device activates.

This 3-phase method adds an extra degree of safety since it completely removes electrical power from all windings when pressure builds up in the capacitor. It helps to prevent catastrophic failures such as case ruptures, explosions, etc. Because the switch is not resettable, it will permanently disconnect the faulty capacitor from the power source at the end of its life.

Ruptured capacitor cases can occur in traditional capacitors if the overpressure disconnect device does not function properly or due to high energy multiple layer self healing events. Voltage transients that are either large in magnitude or with extremely fast rise time may exceed the reaction capabilities of this electromechanical device leaving it unable to safely disconnect the capacitor from the power source. Case ruptures may also occur if the capacitor mounting method does not include clearance above the capacitor for proper activation of the overpressure. Proper operation of this protective device requires more than one half inch of clear space above the capacitor. Violent events may also occur if the capacitor leaks (liquid, air or gas) because pressure will not be able to build up sufficiently to activate the disconnecting device. In this case, the leaking capacitor may remain connected until it ultimately fails catastrophically.

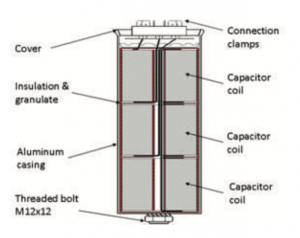

FRAKO AC power capacitors are filled with a dry absorbent granulate, not with liquid or gas. There is no liquid or gas that can leak out. This granulate not only serves to fill empty space in the capacitor case, but it also enhances heat transfer from the windings to the case. Additionally, the diameter and height of individual windings are optimized for low internal temperature rise.

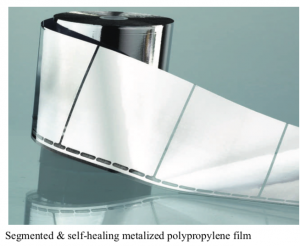

To protect against case ruptures, especially in the event of severe transient over-voltages, FRAKO AC Power Capacitors are all produced with segmented film, self healing metalized film.

The basic concept behind segmented film is that a small section of film which has been electrically weakened thru severe breakdown, or has incurred damaged due to severe overload, will be removed electrically thus maintaining the electrical integrity of the capacitor winding. Small fusible links serve to remove a small section of metalized film when a significant over voltage occurs or when extremely high localized current flows. Rather than have a winding which has multiple self healed points and therefore weakened areas, individual segments are disconnected by vaporized links and will remove affected areas. This feature increases the level of safety, due to over-voltage and overload and extends the usable life of the capacitor.

The use of segmented film limits the amplitude of energy available during a capacitor self healing event, especially those caused by severe transients. This feature adds an important degree of safety for AC capacitors that are used in either power factor or harmonic filter systems.

When capacitors (or other electrical equipment) are liquid filled, the potential for leaking fluid exists. Although oil has favorable qualities from the perspective of cooling and dielectric strength, leaks may present a flame hazard and clean up expense. If fluid leaks out of the device and onto the floor it may cause a slip and fall hazard for unsuspecting personnel.

Since the banning of the use of PCBs in electrical equipment, the transformer and capacitor industry migrated toward the use of alternative dielectric fluids such as mineral oil, vegetable oil, etc. The vegetable oils have a much higher flash point than mineral oil and have become more prevalent than the latter. Today, other than for medium and high voltage applications, dry type transformers are increasingly becoming preferred over liquid filled, primarily to eliminate the adverse effects of oil leakage. Similarly, dry type capacitors offer safety advantages over oil filled capacitors.

Advancements in manufacturing techniques now make dry construction available for low voltage capacitors. The FRAKO manufacturing process adds a small amount of vegetable oil (high flash point) to the metalized film. This is beneficial for thermal heat transfer, dielectric strength and to prevent oxidation of the winding metallization. You’ve heard the expression “an ounce of prevention”, well that applies to their manufacturing process as well. About an ounce of oil is used in each three phase capacitor. This is enough to provide the benefits but without any possible chance of leaking oil. Additionally, capacitors are filled completely with a dry absorptive granulate. If any drops of oil remained after the windings were impregnated, with the oil film, it is fully absorbed by this dry granulate. There is oil where you need it, and no where else. Nothing available to leak out.

Leaking, exploding and ruptured capacitor cases all constitute a problem for the users of power factor and harmonic filter equipment. Leaking, bursting or exploding capacitors can pose safety hazards and undesirable cleanup work. These types of problems became more common after the industry moved away from the use of PCBs.

FRAKO has solved these problems through their innovations in the design and construction of AC power capacitors. Above and beyond the typical self-healing film and two phase disconnection for internal overpressure, FRAKO offers segmented self healing film plus three phase disconnection of the windings in the event of internal overpressure. Additionally, FRAKO has successfully made the transition from liquid filled to dry type capacitors, eliminating the possibility of leaking oil while maintaining high performance with long life expectancy.

Through extensive research and development efforts, FRAKO has achieved valuable design characteristics and manufacturing techniques for AC power capacitors. FRAKO’s design leadership has been recognized through the awarding of several patents.

FRAKO goes above and beyond the industry expectations to achieve safer, stronger AC power capacitors. Their dry type capacitors with segmented self- healing film and true disconnection of all three phase in case of overpressure, are the safer solution for power factor and harmonic filter systems.

Our team at the PQMC Store is here for you. For all inquiries, please do not hesitate to contact us. Our customer service team will contact you promptly.