This application note provides guidance for the proper selection and applying type DD60 capacitors in harmonic filter application. Harmonic filters present more strenuous applications for a capacitor than a typical power factor system. Special care must be taken to properly specify voltage, current and ambient temperature requirements.

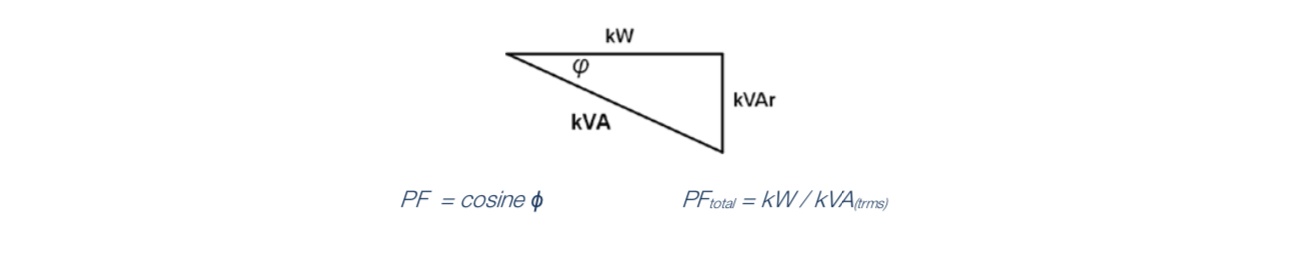

A common power quality objective is to maximize Total Power Factor. Total power factor is the ratio of fundamental frequency kW to true rms (trms) kVA (which includes harmonics). Total Power Factor gives the true picture of kW versus total kVA because it considers both the phase angle displacement between fundamental voltage and current as well as the impact of harmonics on the trms kVA. A good Total Power Factor (near unity) requires both high fundamental frequency power factor and low harmonic distortion.

As adjustable speed drives (ASDs) continue to grow in popularity, due to their energy saving capabilities when operating fans and pumps at low speed, power quality equipment needs have been shifting from that of power factor improvement to harmonic mitigation. The typical fundamental frequency power factor at the input terminals of an ASD is close to unity (often 95% to 99% power factor). AC Motors controlled by VFDs therefore do not require displacement power factor improvement. Nevertheless, harmonic current distortion associated with drives affects power quality and reduces Total Power Factor. Instead of requiring Power Factor Capacitors, motors controlled by drives often require some form of harmonic mitigating equipment (harmonic filters). In many cases where across the line motor starters are replaced with VFDs, there will be less need for power factor correction but greater need for harmonic filtering.

Harmonic filter technology generally falls into two categories: passive or active. Passive filters utilize AC power capacitors and are the focus of this paper. Although variations may be available, the most popular passive harmonic filters are either tuned filters, detuned PFC equipment or wide band filters. Harmonic filter applications induce burdens on capacitors that are typically more severe than normal power factor applications. Harmonics increase the total current flowing in the capacitor as well as the capacitor terminal voltage, especially peak voltage. The kVAR output of the capacitor increases, as does its temperature.

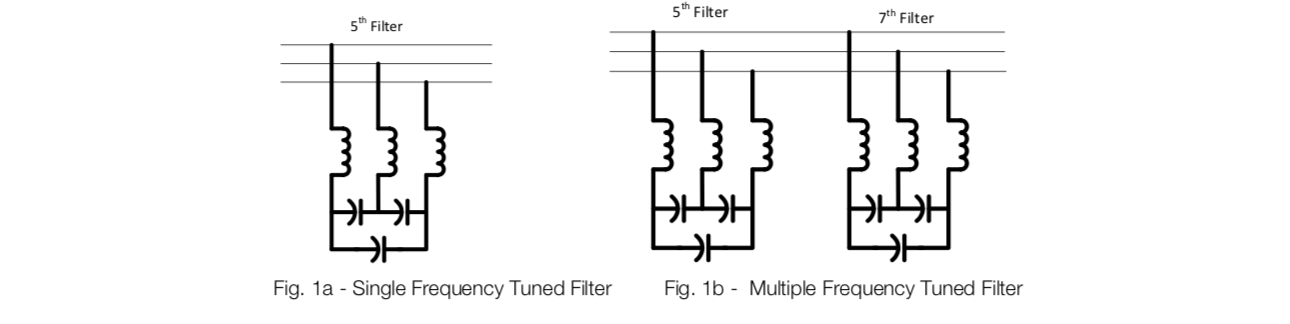

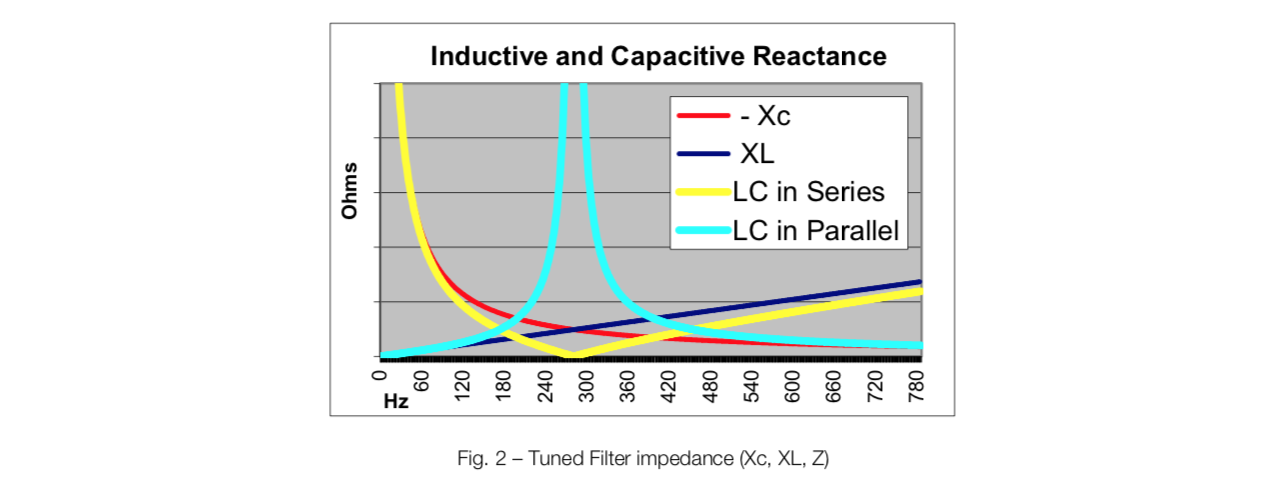

Tuned harmonic filters and detuned PFC systems are formed by the series connection of a reactor (inductor) and an AC capacitor. The inductive (L) / capacitive (C) network is connected in parallel with the power system and will act as a filter for the entire bus. This LC network serves to divert a specific harmonic frequency away from the upstream power system, because the filter presents low impedance to the tuned frequency. The tuned filter may be tuned for a single harmonic frequency or multiple harmonic frequencies. A detuned PFC system tunes the capacitor below harmonic frequencies to prevent it from being overloaded by harmonics.

Inductive reactance (ohms) increases with frequency by the equation XL = 2??? and capacitive reactance (ohms) decreases inversely to the frequency by the equation Xc = 1/(2??C). Inductive reactance is due to the power transformer and upstream generator. Although every power system has inductive reactance, capacitive reactance is only present if capacitors (ie: power factor capacitors) have been added to the system.

A tuned filter has low impedance at its tuned frequency and will cause some current at that frequency to be diverted away from the upstream power system. This type of filter will attract harmonic current from any and all sources connected to the bus and must therefore be sized large enough to handle all of the potential harmonic current. The amount of harmonic current removed vs. continuing upstream is a function of the current divider that exists, at the tuning frequency, between the filter and the upstream power system impedance. At the fundamental frequency, this type of filter is capacitive and therefore can provide fundamental frequency power factor improvement.

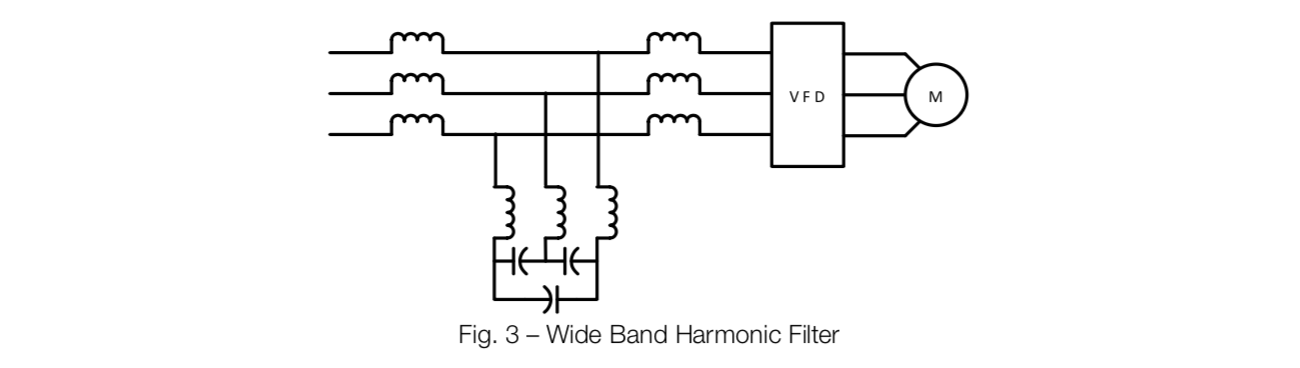

This type of filter is connected in series with an individual non-linear load such as an adjustable speed drive (ASD). It offers low impedance to the fundamental frequency so that fundamental current passes easily to the load. At all frequencies above the fundamental frequency, it has high series impedance, essentially blocking those frequencies.

The typical wide band harmonic filter consists of three stages of filtering: an input stage reactor, an output stage reactor and a tuned filter in between these.

This type of filter is often referred to as a non-resonant type filter because at the input terminals, it makes an ASD look and act like a linear (non-harmonic producing) load. This type of filter does not absorb harmonics from other sources on the same bus. It only filters those harmonics caused by the load connected to the output stage of the filter.

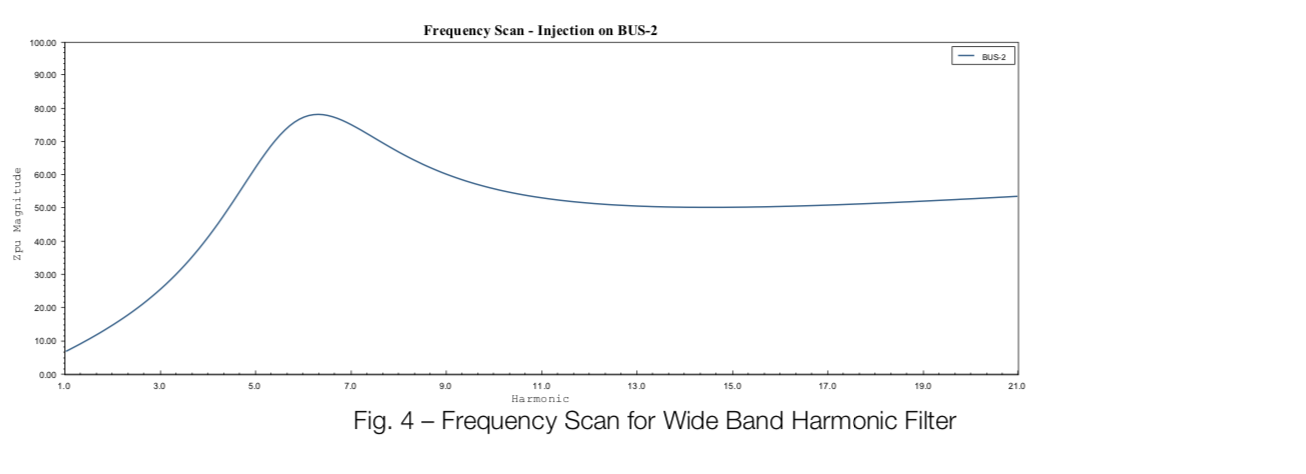

One can see the effect of its filtering by performing a frequency scan at the intermediate point between the input and output stages, where the shunt tuned section is also connected. Here it can be seen (Fig. 4) that there is high impedance at all harmonic frequencies, especially the 5th and 7th harmonics (two most significant harmonics for 3- phase equipment) but low impedance at the fundamental frequency.

The wide band harmonic filter permits fundamental frequency to pass easily, but filters all higher frequencies. Unlike the tuned filter, it does this without creating a resonance point with low impedance near a harmonic frequency.

Regardless which type of filter (or what modification of these types) is used, the critical component for filtering harmonics is the capacitor. It must be assured that the capacitor is capable of handling the true rms current, the true rms and peak voltage, as well as the air temperature that surrounds the capacitor inside of its enclosure. Insufficient capability in any one of these areas will result in premature capacitor failure.

The effectiveness of a harmonic filter is partially a function of the inductor/capacitor tuned frequency. The more precise the inductor and capacitor are, the better will be the filtering. The tighter the tolerance on these key components, the more predictable the performance of the filter will be. Always use components with narrow tolerance bands.

FRAKO Type DD60 & DP60 capacitors have tolerance bands of -0 % to +5%. Capacitor True RMS current

In a harmonic filter application, it is common for the harmonic current to exceed the fundamental frequency capacitor current. This is because often the capacitor is sized at about 25% to 40% of the non-linear load capacity, while the harmonic current distortion may be as much as 40% of the total load current or higher. This harmonic current can flow into the filter capacitor and will increase the true rms capacitor current. If the harmonic current is equal in magnitude to the fundamental current, then the trms capacitor current will be 141% of the fundamental current. Be careful, as many capacitors are rated to handle a maximum current that is 135% of fundamental current.

FRAKO Type DD60 capacitors handle 165% current continuously. Capacitor True RMS Voltage

Capacitor terminal voltage is a function of the capacitor value, the series reactor impedance plus the harmonic spectrum of the current flowing into the capacitor. Capacitor voltage is boosted by the series reactor (typically 5% to 7.5%). Harmonic current flowing into the capacitor causes harmonic voltage and increases the true rms voltage at the capacitor terminals.

The capacitor RMS voltage rating should be determined through engineering analysis. Based upon filter calculations, one can determine the harmonic spectrum of the capacitor terminal voltage. The RMS voltage rating of the capacitor should be determined by analysis or may be estimated as the arithmetic sum of the rms voltages arising from the fundamental plus all harmonic frequencies. This is a conservative method which considers the worst case where harmonic voltages are in phase with the fundamental voltage. The capacitor must be capable of handling both t herms and peak voltage.

FRAKO Type DD60 capacitors handle 110% voltage continuously.

In some filters, it may still be necessary to use a capacitor with an even higher voltage rating.

The voltage that appears on a capacitor when used in a harmonic filter is non-sinusoidal. Due to significant harmonic voltage drops across the series connected filter reactor, significant harmonic voltage may appear at the capacitor. In some cases, the true rms voltage may not seem much different than the bus voltage plus the boosting effect of the reactor, but the crest factor of the voltage can be significantly higher than the normal 1.414. In the worst cases, harmonic voltage at various harmonic frequencies can be approximated as the arithmetic sum of all peak voltages at each harmonic frequency. This cannot be revealed if one considers only the rms voltage. Capacitors must be capable of handling the peak voltage as well as the rms voltage.

Although altitude (elevation above sea level) may only be a consideration in a small percentage of capacitor and harmonic filter applications, it is an indication of the internal relative temperature rise of a capacitor. Most capacitors are suitable for use at elevations up to 1000 meters. Above this, one would typically derate by using higher voltage rated capacitors so the capacitor will operate with reduced internal temperature rise. Capacitors suitable for use at higher elevations will generally be those with lower internal temperature rise under normal operating conditions.

FRAKO Type DD60 capacitors are designed for use at up to 4000 meters (13,124 feet) above sea level.

People normally think of ambient temperature as room air temperature in the area where electrical equipment will be installed. When it comes to capacitors however, it is the temperature of the air surrounding the capacitor itself, inside the enclosure, that really matters. The internal temperature of an enclosure can be 10°C to 20°C hotter than the room air temperature. Heat is the destroyer of electrical and electronic equipment. Capacitor systems often involve reactors, contactors, control transformers, fuses plus power and control circuit wiring. Each of these contributes to the internal temperature rise of the enclosure and thus to temperature of the air surrounding the capacitors. The location of the capacitors also has a lot to do with the temperature of the surrounding air. It makes a difference whether capacitor are installed above or below major heat producers (ie: reactors), or where they are located in the stream of air flow.

To complicate matters, capacitor temperature ratings can be misleading. For example, some capacitors are rated – 40/D, 55°C max. What does this mean? If you think this capacitor is rated for use at 55C you would be wrong. The highest mean over any 24 hour period should not exceed 45C, and the highest mean over the course of one year shall not exceed 35°C. For a short term the temperature may reach 55°C, but the requirement is only one time for up to 48 hours with sinusoidal voltage applied. It is much better to use a capacitor with a continuous ambient temperature rating that is higher than the maximum ambient temperature in the enclosure. If a capacitor is operated in an ambient temperature that is 10°C above its rating, its life will be reduced by at least 50%.

FRAKO Type DD60 capacitors handle 60°C ambient continuously.

Article written by: John Houdek

John Houdek is president and co-owner of Allied Industrial Marketing, Inc. (Cedarburg, WI, USA), a company that specializes in electrical power quality. John serves the power quality industry as an un-biased resource for a variety of power quality services including problem diagnosis, harmonic analysis, filter design, computer simulation, training and seminars as well as technical marketing support for key components used for the assembly of high performance power quality equipment.

Prior to forming Allied Industrial Marketing, John held senior management positions for two electrical power quality equipment manufacturers. John earned an MBA from Keller Graduate School of Management in 1989 and has a bachelor’s degree in electrical engineering technology from MSOE, where he is also a part time lecturer.

John is an adjunct assistant professor at MSOE (Milwaukee School of Engineering) where he teaches a course in electrical power quality. He has presented power quality seminars and training programs throughout North America, in Europe, Asia and South America and has authored many technical papers which have been published or presented throughout the world.

John Houdek

Power Quality Specialists

Allied Industrial Marketing, Inc.

W67 N222 Evergreeen Blvd., Suite 209 Cedarburg, WI 53012 USA

Phone: 1-262-618-2403

Website https://www.alliedindustrialmarketing.com

Email: jahoudek@alliedindustrialmarketing.com

Our team at the PQMC Store is here for you. For all inquiries, please do not hesitate to contact us. Our customer service team will contact you promptly.